Practicum - Learning the Flow of Manufacturing

Graduate students create products one-on-one with professionals

The Practicum program was opened in 2013.

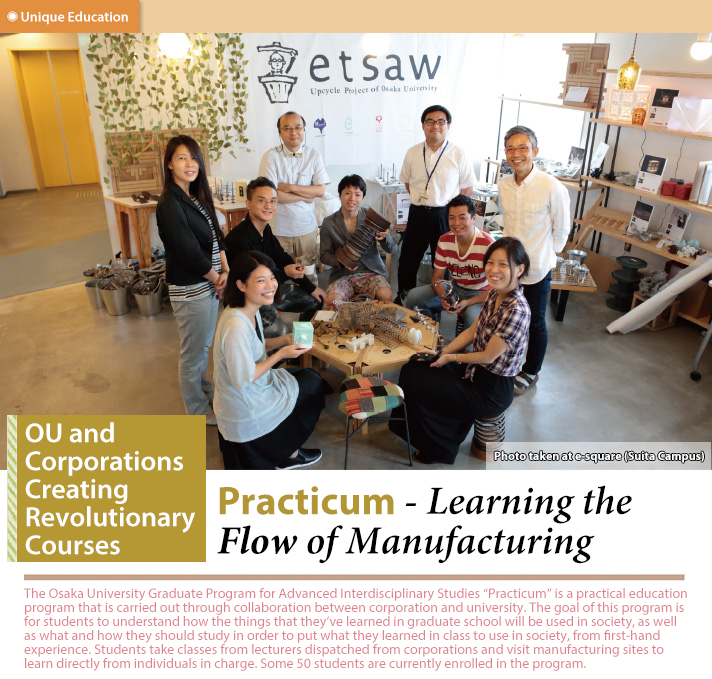

The Office for University-Industry Collaboration's e-square on the Suita Campus offers unique courses for nurturing future entrepreneurs in science and technology in close collaboration with corporations.

With the aim of developing entrepreneurs in science and technology, The Office for University-Industry Collaboration has promoted collaborative and commissioned research with corporations. "This university-wide educational program was created primarily for graduate students, with these accomplishments as its foundation," said Specially Appointed Lecturer HAMADA Norio.

The Practicum program was opened in 2013.

The Office for University-Industry Collaboration's e-square on the Suita Campus offers unique courses for nurturing future entrepreneurs in science and technology in close collaboration with corporations.

With the aim of developing entrepreneurs in science and technology, The Office for University-Industry Collaboration has promoted collaborative and commissioned research with corporations. "This university-wide educational program was created primarily for graduate students, with these accomplishments as its foundation," said Specially Appointed Lecturer HAMADA Norio.

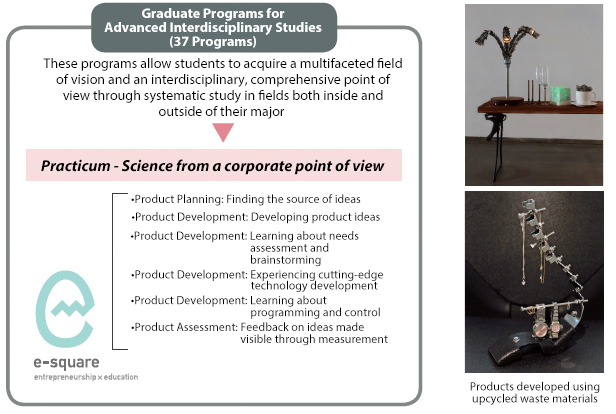

With a formation that is intensely aware of the flow of product development in a corporation, "product planning," "product development," and "product assessment" serve as the main pillars for this program. In "product planning," students acquire skills to gather information and communication ability, such as interviews to dig up ideas and needs. In "product development," students develop their ideas and create business plans for commercialization based on what they have learned about product development, needs surveys, and brainstorming. Finally, in "product assessment," students are involved in the upcycle* of wood waste from factories and experience actual manufacturing. "For example, in the product assessment course, one creator (dispatched from a company) and one student work together to complete a product in a one-on-one setting. This course is characteristic of the 'Practicum' program."

*Upcycle - by adding wood waste from factories to a design, additional value is added and the waste is reborn as a completely new product

Nurturing corporate minds in graduate students in interdisciplinary education

The "Practicum" is a high level minor program in addition to the established curricula of graduate schools. Graduate students who complete 4 of the 6 courses receive a certificate of completion for the high level minor program. Graduate students are also able to take single courses (from these 6 courses), and undergraduates may take courses as well (no credits are given to undergraduate students in these courses). "Other than programming courses, which require basic knowledge in measuring devices and computing machinery, the content of each course is such that even graduate students in liberal arts majors can understand and enjoy. In fact, in product development, liberal arts students often take a leadership role in the course," Dr. Harada added with a smile.

As for what he expects of these students, he says, "I want students to acquire a mind that attempts to create science and technology that is beneficial to society, a spirit that will try anything, and an attitude that will always attempt to find a better solution. At e-square, we have the latest devices, such as 3D printers and laser processing machines, which provide an environment in which students can create prototypes as well. For this reason, there are many students who say that the hurdles involving in manufacturing have been lowered. I'd also like students to acquire the fundamental skills of a member of society through time management when juggling multiple tasks in this program, research activities, and laboratory events, and to become human resources that have the ability to deal with hardships on their own and push forward even in times of adversity." He also mentioned that the network between students in this course is expanding through stimulation that they receive from exchange with graduate students in other fields.

"This program is still under development, so the possibilities are still expanding. Moving forward, we are exploring a way to combine this program with students' own laboratory research to develop their expertise as well. I think this is also a significance of this program."

Aiming for a mature course for both the University and corporations

The program is also investigating collaboration with cooperating corporations. "We aim to be of some assistance to problem-solving in corporations. Through this course, students will propose solutions after getting a close look at the inner workings of a corporation and figuring out its challenges. The good news is that students were able to actually contribute to some corporations in terms of manufacturing. 'Practicum' is a close form of industry-university collaboration through entrepreneurship education. I want to develop this into a course that is meaningful for both university and corporation."

Now entering the program's 4th year, the number of students who participated in this program has reached some 200 individuals. 8 students have fulfilled the requirements for the course and received a certificate of completion upon graduation. "I want to obtain the cooperation of many more corporations and increase the number of courses.

In the future, I want to commercialize the ideas proposed in these courses and incorporate students into the actual scheme of industrialization," said Dr. Hamada on his sizable goals.

Student Interview

I found myself considering starting my own business

KAWASAKI Ayumi

(Department of Biotechnology, Division of Advanced Science and Biotechnology, Graduate School of Engineering)

In my laboratory, I'm involved in research and experiments to make effective use of genetic material of plants. I have a strong desire to create things that will be useful to society, and when I learned of the 'Practicum' program, I knew I wanted to take it. I actually got to experience manufacturing and I learned the importance of connections between people, while at the same time, I was surprised at the unexpected ideas of students from other fields. I was also very happy when my own ideas took shape and were evaluated.

I wanted to become a researcher, but after taking this program, I've started to think it might be interesting to start my own company by using my biological engineering knowledge. It's tough for a graduate student to balance this program and their own laboratory duties, but by taking this program, your world will be that much larger, and you may even be able to find a new you.

Corporate voices

I want students to become individuals

who can think for themselves, take action, and reach their goals

I want students to become individuals

who can think for themselves, take action, and reach their goals

KOYAMA Akio (Chief, Planning and Development Division, Sanplatec Corp.)

Our company is a maker of experimental equipment and devices, and in 'Practicum,' I'm in charge of the Product Development course. I put great value on giving students the experience of being involved in specific processes to commercialize their own ideas, through which I hope they will become able to think for themselves, take action, and reach their goals.

Many barriers face a product on its path to commercialization, but I was impressed that students were even proposing different variations of their product at the final presentation.

Moving forward, if communication between students with different knowledge and techniques becomes even closer, ideas in product development will advance.

I hope that actual new products will be created in this course, and that this will that this will increase students' self-confidence.

--

2-1-3 Doshin, Kita-ku, Osaka

Established in 1960, Sanplatec manufactures and sells laboratory equipment. In 2012, Sanplatec published the first experimental instrument catalog for female researchers, "Plantine." In the past few years, the company has entered the field of life sciences, with their live iPS cell transportation system, "iP-TEC," gathering a lot of attention since its release.