Changing world manufacturing through an innovative manufacturing process using microwaves

Striving to become an international base of microwave chemistry research

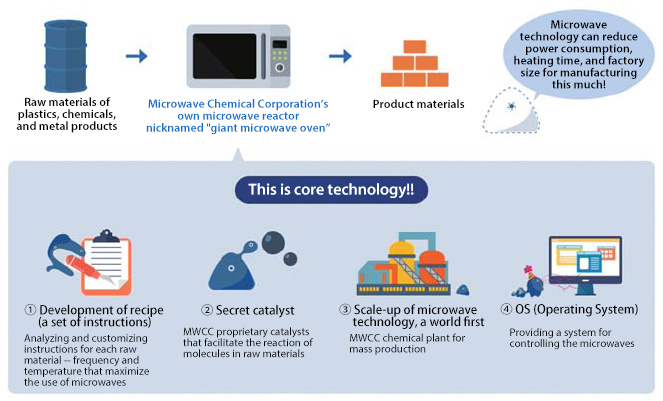

Microwaves are a type of electromagnetic wave that are used in microwave ovens, which directly vibrate specific molecules in a substance and rapidly heat them from the inside. While its effectiveness in manufacturing is widely recognized, expanding its production capacity for commercialization was considered difficult in terms of optimum frequency selection, temperature control, and safety.

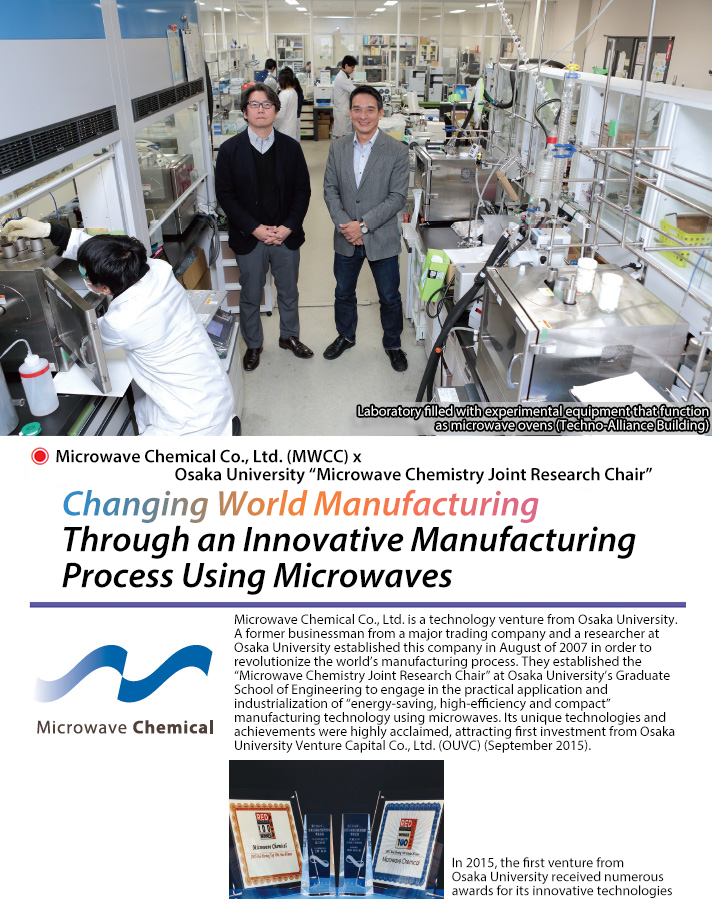

Microwave Chemical Co., Ltd. (MWCC) established the “Microwave Chemistry Joint Research Chair” as a university-industry collaboration in April of 2010. Based on the research results of the chair, the company provides domestic and overseas chemical manufacturers with their progressive technologies to fundamentally change the chemical manufacturing process, aiming to spark process innovation in the chemical industry.

Joint Research Chairs can take advantage of drastic strategies

Why did they establish this joint research chair? Specially Appointed Associate Professor Yasunori TSUKAHARA, who is also a MWCC Director and CSO, said, “Under the slogan of ‘Industry on Campus,’ Osaka University focused on industrialization of technologies they developed. They established the system of Joint Research Chairs as part of their efforts. Previously, general joint research spending was on the one to two million yen level, so it was difficult to take a drastic approach. We thought a Joint Research Chair, in which a company can invest 20 to 30 million yen, could accelerate the practical use of microwave technology, including basic research, development of manufacturing processes, and mass production, and realize its industrialization.”

The chemical industry has a market scale of 500 trillion yen

The chemical industry, which rose in the second half of the nineteenth century, has not seen major innovation in over for more than a century. They produced chemical products not by directly heating materials but by indirectly heating a reactor as a whole.The energy necessary for the production reached “30% of the entire industry, accounting for 17% of carbon dioxide emissions,” with conventional chemical plants occupying a large space. Mr. Iwao Yoshino, President and CEO of MWCC, feels the great potential in the development of microwave technology, saying, “I want to reduce energy consumption to one third and factory sites to one fifth of their current states through microwave chemistry technology. So if even just 1% of the conventional manufacturing process was supplanted by the microwave process, it would be a market worth 5 trillion yen."

Repeated trial & error

This joint research chair developed two major basic technologies. One is a technology to design chemical reactions at the molecular level, such as determining frequencies that promote chemical reactions of product materials. The other is a technology to scale up these chemical reactions to the chemical plant level: a technique for manipulating microwaves, such as how to apply microwave radiation in microwave reactors correctly and uniformly. “Many chemical manufacturers have tried to use microwave technology, but failed. Our joint research chair also went through repeated trial and error,” said Specially Appointed Associate Professor Tsukahara.

However, people from different fields thought outside of the box, realizing the world’s first plant of mass production. Thinking back, he said, “Access to special analytical instruments and reference management software at Osaka University was also a factor to our success.” And then, in March of 2014, they completed the world’s first large-scale microwave chemical factory (their own factory) in Suminoe-Ku, Osaka City. “We were able to demonstrate to the chemical industry that it really was possible to make products safely using microwaves.”

Venture launched based on research results

About the reason for launching this venture with President Yoshino, Specially Appointed Associate Professor Tsukahara said, “I thought even if we launch a niche business with superior technology, the market would be limited. In order to spread the manufacturing process using microwaves throughout the world, the best strategy would be to launch the company ourselves targeting the whole process from research through to commercialization.”

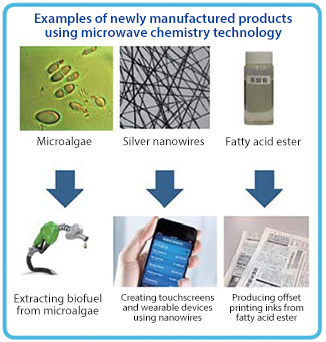

Meanwhile, after retiring from a major trading company, President Yoshino was considering launching a venture while engaged in consulting and other activities in the United States. “Microwave chemistry is a method to combine familiar technologies used in microwave ovens with catalysts, simulations, and scale-up technologies for mass production. I felt it made good business sense.” Currently, they are engaged in the development of manufacturing processes for polymer production with the world’s largest chemical manufacturer BASF (Germany), expanding their business internationally.

Possible fourth industrial revolution

Investment from Osaka University Venture Capital Co., Ltd. (OUVC) financially supports MWCC’s wide-ranging development of proprietary manufacturing process of ink materials, food additives, electronic materials, and plastics using microwaves. They will use the money for building mass production facilities and developing fundamental technologies in order to accelerate their business. President Yoshino says, “Moving forward, conversion of technologies in manufacturing could lead to a fourth industrial revolution.”

Specially Appointed Associate Professor Tsukahara eagerly proclaimed, “I want this technology to spread from Japan to the world and revolutionize the world’s chemical industry.”